Warehouse Inventories

The term warehouse inventory refers to the stored raw materials, semi-processed goods, or finished goods that are kept in the storage of the business for further processing or sale. A warehouse is a physical building or store that is used by a business to keep its extra inventory or stock. Inventory, e.g. of finished products, can also be kept in the factory, shop, or with resellers, but, the warehouse inventory, particularly, is the stock that is kept in the warehouse or storage place of a company.

The warehouse inventory, usually, is not used for the end customer. It is like a source of distribution to the production center and selling facility or the resellers. Generally, the level of inventory kept in the warehouse is larger than the inventories kept in the in-house storage facilities or display centers.

Warehouse inventories are considered an important asset in the financial statements of a business. However, they do not only hold financial value for a company but they are also essential for the smooth operations of a business as well. The following points signify the importance of different warehouse inventories and highlight why businesses pay special attention to managing their warehouse inventories:

- The inventory of raw materials is essential for even production. If the goods are to be produced but the raw materials are not present, it might hinder the production process until the availability of the raw materials.

- The inventory of semi-processed goods helps in maintaining the production and sale process. For instance, if the customer requests for a product within a short deadline, the semi-processed inventory aids in making the delivery possible.

- Through the inventory of finished or ready-to-sell products, the sale becomes probable whenever there is an available reseller or the level of products in the shop becomes lower than required.

In addition to the smooth operations and sales functions of a business, the warehouse inventory is also related to budgeting and forecasting. Therefore, only having warehouse inventory is not sufficient, rather, managing it at proper levels is very crucial to a business. This is referred to as inventory management. If higher levels of inventory are kept in the warehouse that is required, it indicates that cash has been unnecessarily stuck in the inventory which could have been put to better or productive use.

On the contrary, if for the budgeted production, sufficient raw materials are not available in the warehouse, it would take a toll on the company’s profits. This makes it extremely important to manage the ordering and delivery of raw materials as well as leveling the semi-finished and finished products to cut the slack time in operations and other business functions to the maximum extent possible.

Therefore, tracking, recording, and managing warehouse inventory is significant and companies pay extra heed to it, as it directly affects their financials. These days, there are many software, applications, and programs available that ease the task of inventory management and improve the efficiency and effectiveness of operations for businesses.

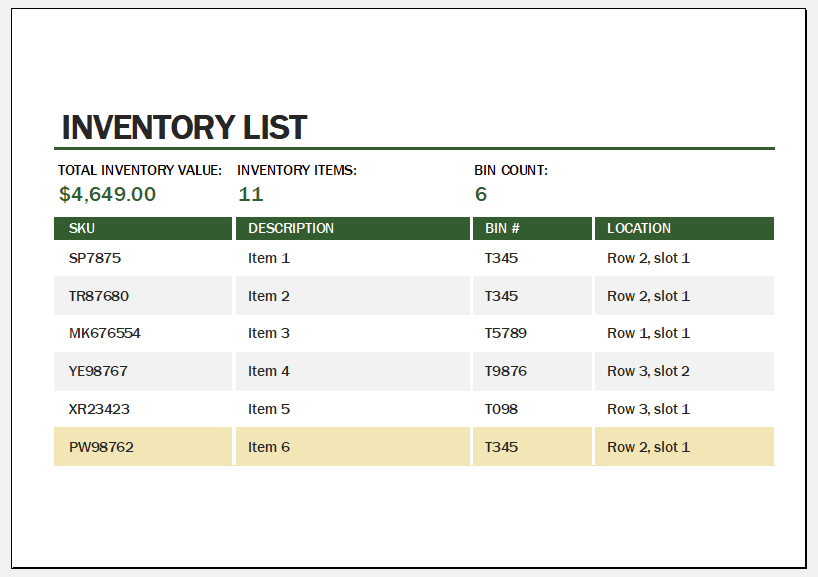

Preview of Template

Format: MS Excel [.xlsx]

- Student Entry & Exit Log

- Gantt Chart for Smaller Projects

- Behavior Log of Child for Schools

- Loan Repayment Tracker

- Product Sales Tracker Template

- Debit Memo Template for Excel

- Winter Attire Inventory

- Financial Projections Worksheet

- Employee Absence Tracker

- Weekly Sales Report Template

- Budget Vs Actual Statement

- Remote Work Attendance Tracker

- Mileage Expense Report Template

- Fitness Calendar Template

- Project Gantt Chart

← Previous Article

Petty Cash LogsNext Article →

New Home Construction Expense Spreadsheet